Sewerkote Duramer 1030 Series protective coating system is a two-component, corrosion-resistant 100% polyurea coating system that bridges gaps in concrete up to 1/4″ wide/deep for use in new or rehab concrete manholes, wet wells, lift stations, pipe, wastewater treatment structures, and aerial sewer pipes.

Photo by Scott Rodgerson

Duramer® Advantages:

- Polyurea – Excellent hydrolysis and moisture resistance

- Thick – film thicknesses of any depth desired

- Elastomeric – shifting environment underground, resists impact, other fracturing agents

- Pot life – 15- 30 minutes, longer for the primer – gives excellent penetration and bonding

- Multi-Coat System – prevents pinholes from lining up

- 40 mil one-pass intermediate coat depth – easily bridges cracks and bug-holes up to 3/8″ across, fills in larger, shallow bug-holes

- Each coat colored differently – allows visual inspection to ensure each coating has completely covered underlying coat

- Resistant to acids, caustics, and gases

- Resistant to mold and fungus

- Forms a cohesive bond to the surface to which it is

applied - Cures quickly

- Wide range of mil coverage (as specified)

- Up to 250 mils of thickness (60 – 100 mils standard)

- Safe — non-toxic, non-carcinogenic

View the DURAMER® 1030 SERIES SEWER COMPONENT PROTECTIVE COATING SYSTEM coating specs. Download pdf

View an extract from the City of Raleigh Public Utilities Handbook approving use of the DURAMER® SYSTEM. Download pdf

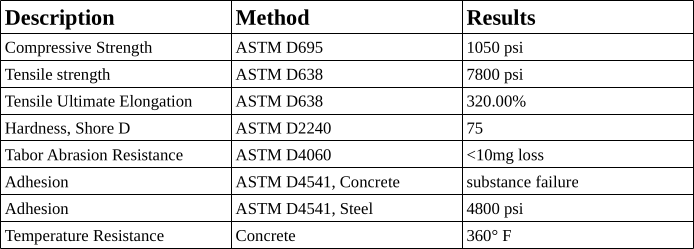

Specifications*

*Properties of pure polymer